The “Super Copra Process” Comes to the Philippines, Attains 40% Capacity Increases |

|

The Anderson Hivex™ Expander has once again demonstrated superior ability to increase Expeller® capacity and oil production for yet another important oil staple, Copra oil. |

Hivex™ Technology, A Brief Overview

|

|

Use of Expander-Dryer® expanders for preparing oilseeds for more efficient solvent extraction was developed and patented by Anderson International in 1961 for rice bran, soybeans, and cottonseed. By 1988, oilseed processors required expander technology capable of processing seeds, beans, and nuts with higher oil content; thus Hivex™ technology was created. The invention was found unique and patents were awarded in 1988. Expander-Dryer® expanders, whether solid-walled or Hivex™, utilize the ability to combine HTST (high temperature short time) cooking with high rotational shear to rupture oil cells and restructure material density. This improves solvent extraction up to 100% and Expeller® operations up to 300%. Expander technology reduces steam and electrical energy requirements in addition to improving the quality of the oil produced. |

The Key to Operational Efficiencies |

|

When you purchase genuine Anderson replacement parts, you not only acquire high-quality parts, but you also establish a relationship with certified Anderson technicians. Purchasing non-Anderson parts risks the efficiency of your operations - leading to higher energy costs and lower production. Genuine Anderson parts are designed with efficiency and value of the product in mind. Joe Busser, a long time Anderson Expeller® designer, once stated “Send your best technician to visit a different mill each month for two years, and he will gain the same experience he might have gained in twenty years in the same mill.” What is the point? This is exactly what Anderson technicians have been doing since 1901. They travel to mills around the world working with each client to improve operational efficiency. What is the value of Anderson experience to a mill operator? Tens of thousands of U.S. dollars per year in yield improvements, energy savings, and part replacement costs. |

|

Attack your bottom line - insist on Anderson replacement parts |

Hivex™ Selection Parameters |

|

This information is dramatic when you relate it to the following facts*: · 40% increase in capacity on total plant basis by use of one Anderson Hivex™ Cone Choke Expander using a 200 HP motor to process 175 MT/D Copra · Per ton reduction in steam consumption · Reduction in electrical energy requirements · Extracted oil color and FFA improved significantly * Oil mills surveyed had multiple Anderson Twin Motor Super Duos |

|

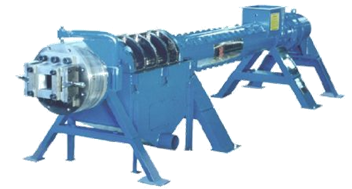

Dox-Hivex™ Expander |

|

Inventor of Advanced Processing Technology |

|

Copra |

|

With over a century of service, the mission of Anderson International is to create an environment whereby all who interact with us experience a time honored relationship built on |

|

MODEL NUMBER |

CAPACITY RANGE (MT/DAY) |

HORSEPOWER RANGE (CONN. HP) |

SHIPPING DIMENSIONS (LxWxH) |

SHIPPING WEIGHT |

||

|

FT. |

MT. |

LBS. |

KGS. |

|||

|

HIVEX™88cc |

175-200 |

150-200 |

12x4x4 |

3.7x1.2x1.2 |

4400 |

1995 |

|

HIVEX™1212cc |

300-400 |

300-400 |

32x5.5x5.5 |

9.8x1.7x1.7 |

10500 |

4762 |